by Dave Nordling, Reaction Research Society

The RRS had a short firing event at the Mojave Test Area on April 14, 2024. I was the pyrotechnic operator in charge that day. Although less rain fell than at prior events, the cold spring weather at Koehn (not so) Dry Lake remained but with low winds.

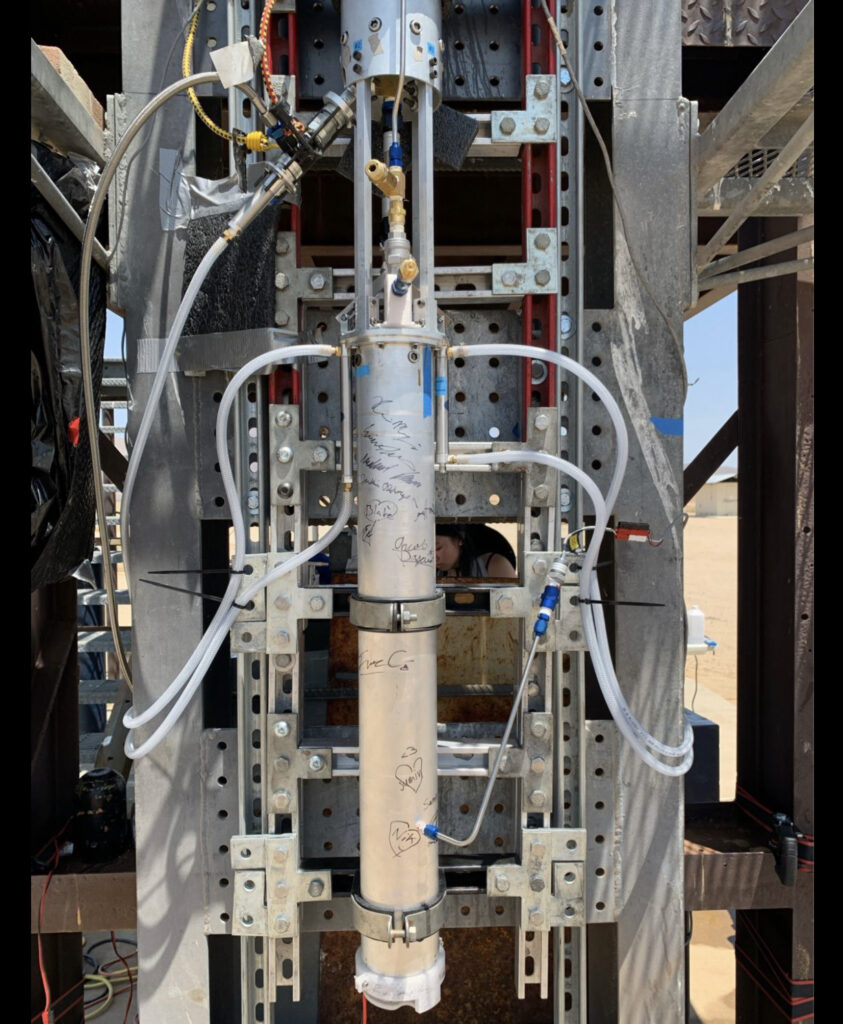

Rushd Julfiker, our director of research, had built his commercial hybrid motor and mounted it for a static firing. The Contrails 38mm, 16-inch motor is the same model I’ve used in the past with some success. Dimitri Timohovich also apprenticed under me and oversaw operations including remote fill and drain operations. Although a hybrid motor has a solid fuel grain, the compressed liquid oxidizer constitutes a liquid rocket classification by CALFIRE standards.

Dimitri Timohovich had built a portable switch box which I have used in prior operations. It simplifies connections and has the features necessary to assure safe and compliant operations. Rushd managed a good fill operation and a clean ignition. Severing the nylon feedline often requires a boosted charge on top of the electric match. A small portion of aluminum/HTPB/AP composite grain is sufficient to cleanly sever the line while assuring sufficient ignition energy to start the fuel grain burning in the flow of the exiting nitrous oxide.

The basic objective of loading and static firing a hybrid motor at the RRS MTA was met. Rushd and Dimitri are both seeking their Class 1 pyro-op licenses and this experience adds to their growing base. After safing the nitrous system, the motor and mounting was removed and stored for a reloading later. Rushd intends to fire again at a later date, but with a load cell in the system to record thrust.

Dimitri and I observed the restroom facility (Bldg 12) at the MTA now has a functional shower inside and a working hot water system. We thank Osvaldo Tarditti for making several trips to the MTA to complete this amenity for our members and guests.

Dimitri and I discussed and examined the propellant feed system for the upcoming LACMA project with American Artist. Most fittings were present, but some changes to the schematic were necessary to simplify our first firing operations expected next month in May 2024.

For those interested in using the RRS MTA, contact the RRS president.