by Keith Yoerg (RRS Secretary)

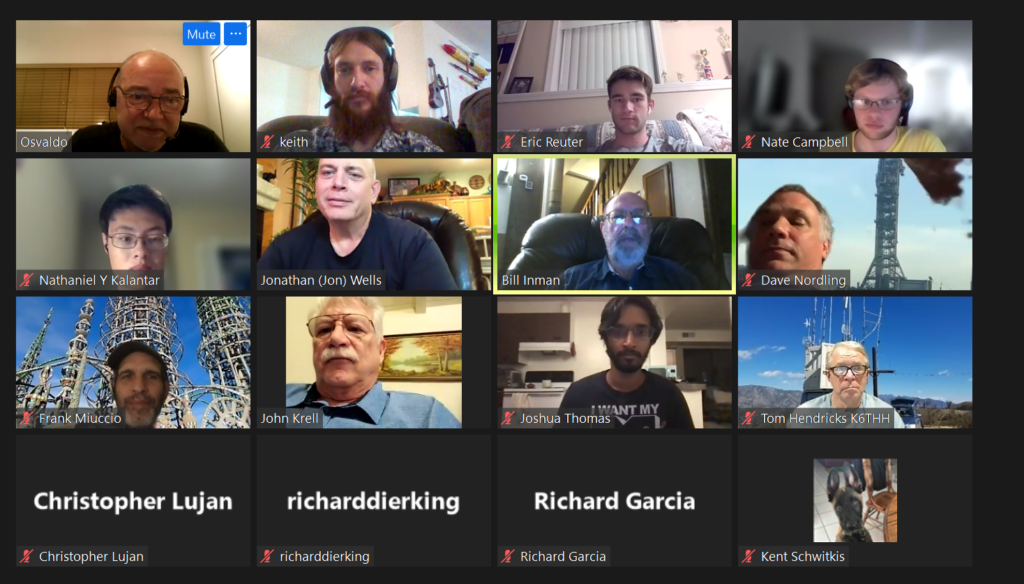

The latest meeting of the Reaction Research Society took place Friday, September 10th and had 16 attendees, including several members of the University of Michigan Aeronautical Science Association (MASA) team which conducted a long campaign of testing at our MTA site last month. After brief hellos & a short discussion on updates to this website, we got the meeting rolling with a presentation from the MASA team debriefing us on their August tests.

PRESENTATION ON MASA CAMPAIGN AT THE MTA

4 members of the MASA team who were present for the long campaign of testing at the MTA site were at the meeting and provided a presentation detailing how the nearly 2 weeks of work went for the team. A detailed write-up from RRS member Dave Nordling who was on site assisting for some of that time is available here.

While the end goal of conducting a hot fire test was not accomplished, there was a ton of great work and learning opportunities for both the MASA team and the RRS. The first challenge for the MASA team was in driving their equipment all the way from Michigan to Southern California. Unfortunately, they had some equipment suffer damage during the trip when their smaller “Ground Support Equipment” (GSE) trailer broke through the plywood floor of their larger travel trailer. This required them to stop in Texas and complete repairs to the travel trailer before continuing on to the MTA site.

Once at the site, the MASA team set up a 2-shift schedule (9am – 6pm and 5pm – 12am) effectively working 18-hour days to conduct the activities required for their tests. Many of these tasks took a lot longer than the team had anticipated, in particular with the supply and delivery of the gas & cryogenics needed. The MASA team was originally in contact with Airgas, but their communication was with the office closer to their home in the Midwest and not the Southern California branch. Ultimately sorting through those issues proved to be too difficult to secure a delivery while the team was at the MTA, but fortunately they were able to work with Praxair to secure a supply of the gas and cryo.

Once the gas and cryogenics were at the site, the team was able to complete pressure tests of the fuel side of the system, and were ultimately able to perform 2 coldflow tests through the entire system near their target pressures. These tests revealed many more areas for design improvements that the team hopes to implement, including reducing fittings, changing the location of vents and drains, and possibly even replacing the LOx and fuel tanks.

This campaign goes down in the books as the longest to ever take place in RRS history, and proved to be challenging for both the MASA team and the RRS. Several society members graciously volunteered their time to help make this testing effort possible, and the experience revealed many ways that the society could improve our procedures to better support extensive tests like this. Namely: limiting the duration of a test period to no longer than 1 consecutive week, requesting that some members of University staff be on-site when these long campaigns take place, and requiring a longer notice time before approving this sort of test were all brought up by RRS president Osvaldo.

PERMANENT BATHROOM

Progress is continuing on the permanent RRS Bathroom structure. Work on cutting holes for doors and windows has been completed on the 20-foot shipping container and delivery is expected imminently to the new work site at Wilbur’s hangar. The next stages of construction including adding plumbing, fixtures, and the doors and windows, and Osvaldo has already acquired some of these items to install

SEPTEMBER MTA EVENT & WORK PARTY

The USC Rocket Propulsion Lab (USCRPL) plan to be out at the MTA site from Friday, September 24th – Sunday, September 26th to conduct a static fire of an 8″ diameter solid rocket motor. The first few days will consist of prep work and the firing is planned on that Sunday. Several members including Bill Inman and John Krell indicated in the meeting that they have stepped up to the Yoerg Challenge and built model rocket kits to fly at the MTA. This will give us a great excuse to test out the new PVC wire rail launchers as well as the newly purchased Cobra wireless firing system.

In addition, the society has decided to use Sunday, September 26th as the date for our annual “Work Party” to perform maintenance and cleaning tasks at the MTA site. The expected tasks we would like to complete are:

- Weld the plate on the vertical test stand

- Removal of dry vegetation

- Move drum of RP1 (from MASA testing) into one of the lockable containers

- Fix the 2 broken latches on the Dosa Building roll door

- Prep/measurements in area for new container bathroom

YOUTH ROCKETRY CLASS

RRS Vice President Frank updated the membership on the upcoming youth rocketry class in Boyle Heights with details on the schedule and overall plan. As opposed to 2 alternating classes, we will now be working with a single class of up to 30 students. The classes will run every Friday starting on September 24th, with a launch planned at the MTA site on November 13th. The plan is for each student to build their own Estes Baby Bertha kit and fly it twice on launch day. RRS Secretary Keith is currently working on 3D printing fin alignment jigs for the students, which will help in both teaching the students about that technology as well as properly installing straight & aligned fins on their rocket kits.

MISCELLANEOUS DISCUSSION

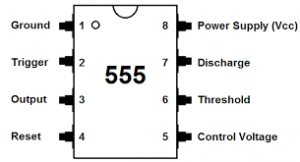

The end of the meeting consisted mostly of miscellaneous discussions around the various projects that RRS members are currently working on. Some of the highlights included John Krell’s new, very small (20x80mm) electronics board capable of collecting 7 channels of data onboard a flight, with over half of those channels at 500 Hz! Bill Inman updated members on the progress with his Solar Cat steam rocket, and there was a brief discussion of ham radio operations with Tom Hendricks sharing some of his wealth of knowledge in that subject. Overall it was a fun meeting with a lot of good discussion & participation from the membership.

NEXT MONTHLY MEETING

The next RRS monthly meeting will be held virtually on Friday, October 8th at 7:30 pm pacific time. Current members will receive an invite via e-mail the week of the meeting. Non-members (or members who have not received recent invites) can request an invitation by sending an email to:

secretary@rrs.org

Please check your spam folders and add secretary@rrs.org to your email whitelist to make sure you receive the invitation.