by the Reaction Research Society

The Reaction Research Society held its first launch event of the new year on Saturday, January 9, 2021. Dave Nordling was the pyro-op in charge. We had a couple rockets prepared and some maintenance work we wanted to continue. Dmitri Timohovich brought his whole family to the event and we enjoyed grilled burgers there at the Mojave Test Area. The January winds were light and cool that day. It was a good day for launch.

Wolfram Blume brought his two-stage rocket, the Gas Guzzler. His ramjet upper stage was rebuilt from last year’s unfortunate breakage when dropped during loading on the launch rail last year. 3D-printed plastic parts can sometimes be very brittle and care must be taken.

The 1515 launch rail was put into position with some help from Bill Inman and a few others. Bill Inman is still working on his solar tracker for his latest iteration of the Scalded Cat. He made the trip from Carson City to the Mojave Test Area to help others with operations and we were very thankful.

Wolfram was able to mount his booster stage on the rails and carefully erect the launcher. The booster uses a commercial solid motor, an Aerotech “K” motor.

The ramjet for this first flight was loaded with water to simulate the weight, but would not be fired. The primary goal was to demonstrate the staging and recovery systems powered only by the booster. Wolfram went back to the loading area to complete the preparations of the upper stage. During a system checkout, the parachute deployment charge fired. After some careful examination, the source of the problem seemed to be related to errant software commands. Wolfram aborted his launch attempt and returned with his rocket stages for further examination back in Los Angeles. Although the charges could be reloaded, he could not be certain that an early parachute deployment would occur and wreck his vehicle during flight.

Dmitri Timohovich and Waldo Stakes worked on completing the welding of the new steel plate on the vertical test stand. This plate on the vertical test stand was damaged during a test failure many years back and late last year was finally cut out and the space grinded to fit a replacement plate. Unfortunately, the stick welding system would require a different type of welder and a more powerful source to drop a reliable weld. The welding of the plate will be reattempted at the next event.

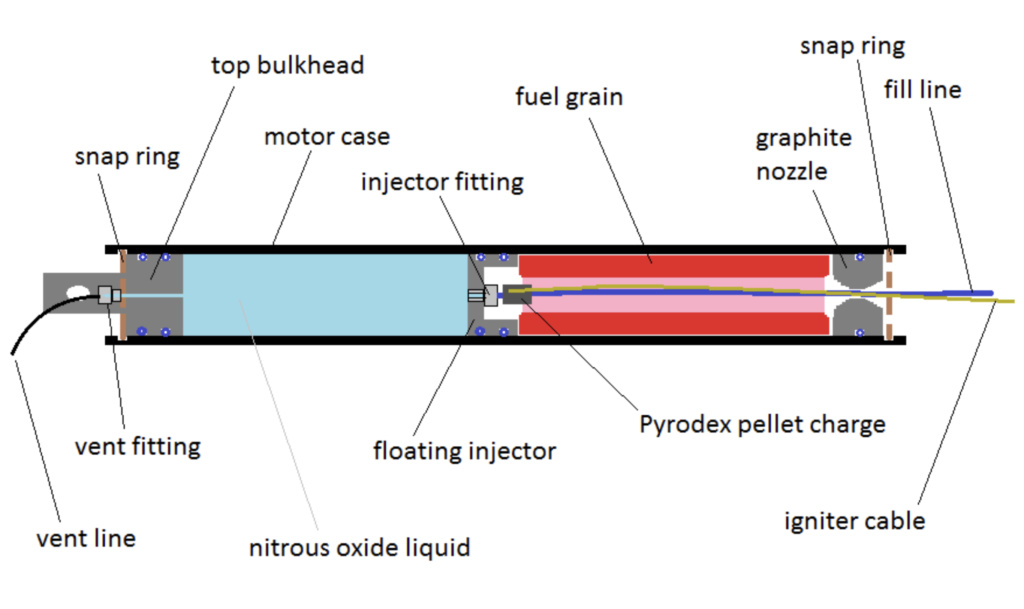

The second launch of the day would be Dave Nordling’s nitrous oxide hybrid rocket. This 38mm H-sized commercial hybrid motor kit from Contrails Rocketry (H-222 model) had a modified igniter and was mounted in a new 4-inch body made by Larry Hoffing. The prior launch attempt had issues with severing the nylon plastic filling line so the ignition energy was increased with small bit of composite solid propellant ignited by an electric match.

Several minor problems occurred during launch preparations. The nitrous bottle and manifold filling system was working well but the electrical control box failed during tests. After some discussion, the defective switch box was removed and we were able to fire and get a clean launch

We repacked the motor before launch and adjusted the vent tube to be more visible. The filling of the rocket went quickly and smoothly, only about 20 seconds before the white stream of liquid could be seen. The filling was stopped and with a short five-count and the rocket was fired. The rocket came off the rails quickly and it seemed that the modified igniter worked. The big problem was the parachute recovery switch wasn’t turned on before launch. This simple oversight would mean a rebuild would be necessary.

The rocket was recovered on the north end of the MTA site. It only seemed to reach about 300 feet of altitude. Unfortunately the ballistic landing broke both stages and the internal motor mounts and a complete rebuild is necessary. The motor case was parts were in tact and so it was extracted and will be reloaded,

Beckie Timohovich recorded the hybrid flight on her phone, The rocket seemed to immediately curve to the north off the rails opposite of the wind. It seems that the nylon fill line might be still holding fast despite the added solid propellant charge. The 3/16-inch nylon plastic line being strong enough to hold back the 900 psi nitrous pressure, it also poses a challenge to cut cleanly from the ignition charge. A static firing of the motor will be done next to get a better look at how well the fill line severs and measure the thrust curve directly..

After recovering the hybrid rocket and putting away the equipment, we flew a water rocket for Dmitri’s young son. Although very simple, these things are very fun.

The event was a partial success and there is more work to be done on our facilities including adding a new toilet facility at our site and welding in the plate on the vertical test stand. The next hybrid rocket launch may be a couple months away, but Bill Inman may have his next design of his solar heated steam rocket ready for launch af fhe MTA in a few weeks. He had his first successful flight in the Nevada desert just before Christmas. He is getting ready for a flight from the RRS MTA.

Wolfram seemed confident that he too might be ready to try his first launch of the Gas Guzzler at about that same time. If the next launch event occurs before the next monthly meeting on February 12, 2021, the announcement will come through the society email list.

erotik shop

erotik shop

erotik shop

erotik shop

erotik shop

erotik shop

erotik shop

erotik shop

erotik shop

erotik shop

erotik shop

erotik shop

erotik shop

erotik shop

erotik shop

erotik shop

erotik shop

erotik shop

erotik shop

erotik shop

erotik shop

erotik shop

erotik shop

erotik shop

erotik shop

erotik shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop

sex shop