by Joel Cool-Panama, Secretary, RRS.ORG

The Reaction Research Society held its monthly meeting at the Compton/Woodley Airport location, March 10th, at 7:30 PM PST.

Agenda topics of the meeting were:

- Jim Gross video watch in San Fernando

- Symposium

- MTA Upgrades:

- MTA Restroom

- Restroom locks

- Blockhouse

- 60 ft launch rail

- Fencing

- New generator

- UCLA 3/2/23

- Nickerson Gardens, 3/18

- Claybaugh launch 4/22, 4/29

- Polaris Propulsion MTA use, August/September

- Polaris Propulsion meeting, March 14th

- American Artist

- FAR solid motor class

- Expansion of MTA use

- Plastic bin donations

Past Events

UCLA was scheduled to use the MTA on March 2nd. However, they had to reschedule, and are now due to use the MTA on March 18th. As a part of their use of the MTA, UCLA has agreed to clear some brush on the property on the society’s behalf.

Yet more progress has been made on the MTA restroom project. Though the water pump is not yet running, the shower is operational. Also, Dimitri has been looking into high quality locks for the MTA, having spend $60 so far on the project.

Current Events

Claybaugh is currently working on his next launch at the MTA. As of now, he is scheduled to launch on April 22nd.

As previously mentioned, society member Dimitri is researching high quality locks for the MTA. The ones at the site now are typical residential locks, and have withstood the elements poorly since their installation. The ones Dimitri is currently looking into are better resistant to dust, being used at mines and quarries. The new locks can all be keyed so that the whole facility will only make use of a handful of keys, making keeping a whole set easier.

Jim Gross has also confirmed that his video watch party will be held at his home in San Fernando. Though he is apparently open to hosting future watch parties online, it seems that on this occasion he plans to host the party exclusively in-person. He also is looking into getting an educational allowance from the publisher, for his watch parties.

The RRS symposium is now certainly set to be held at the Mary Star of the Sea High School, in San Pedro, Los Angeles. The society will be arriving early to do necessary preparations for the day, and will likewise do some setup the night before, before or after our monthly meeting, to be held at the same location. Frank has already obtained the keys to the campus, so we will be free to setup before the day of.

In regards to our preparations, it’s been noted that we should seek out Fire Marshall approal for a model rocket, if we are to launch one at the symposium. Mary Star will handle food service for us, and we will need to keep an eye out for vandalism to their campus. We also need to check the quality of their internet service, and to obtain signs and easels.

In regards to attendance of the symposium, a number of groups have confirmed their attendance or absence at this time. FAR has confirmed that they will not be at the symposium. The Air Force might make an attendance, and ROC is expected to come as well. There is also a desire to reach out to Civil Air Control. Over all, it’s been noted that the symposium attendance will have fewer schools, with a greater industry presence.

Society Treasurer Larry has made some progress in regards to the new Blockhouse project. He’s made contact with National Concrete, who can build a new blockhouse, and has received an estimate. This same group has been used by the society previously for the restroom concrete pads.The society has recently accepted the donation of a telescoping tower. The tower is about 50 to 60 feet in length, and the donor is asking for a tax write-off in return.

Headway has also been made in constructing new MTA fencing. Ed’s Fencing has given an estimate of $100k. Their estimate includes a 6-foot high mendable fence, with concrete posts 3 feet in the ground. Alternatives cheaper than this have been proposed, including a simple razor wire fence, by Dimitri.

Another project has also been undertaken for the MTA. Society Secretary Joel has been delegated the responsiblity of improving the MTA’s electrical infrastructure. The current generator used at the site is owned by Polaris Propulsion, and it’s been noted that it is not clean burning. There is a desire to purchase a cleaner and more efficent 20kw generator, as well as to add solar to the electrical infrastructure. It’s been recommended that Osvaldo be contacted in regards to this project.

Frank’s class in Nickerson Gardens is currently set to launch their rockets on March 18th. Frank’s current plan is to launch each rocket three times.

Responses have been received from members regarding FAR’s solid motor class. The class will span over three weeks, and will be led by John Newman. It’s been noted that a single class uses 8 feet of propellant and that a class only takes 4 persons. The classes will be $10 per person per day.

Future Events

Polaris Propulsion is going to make use of the MTA later in the year, starting in August, and ending in September.

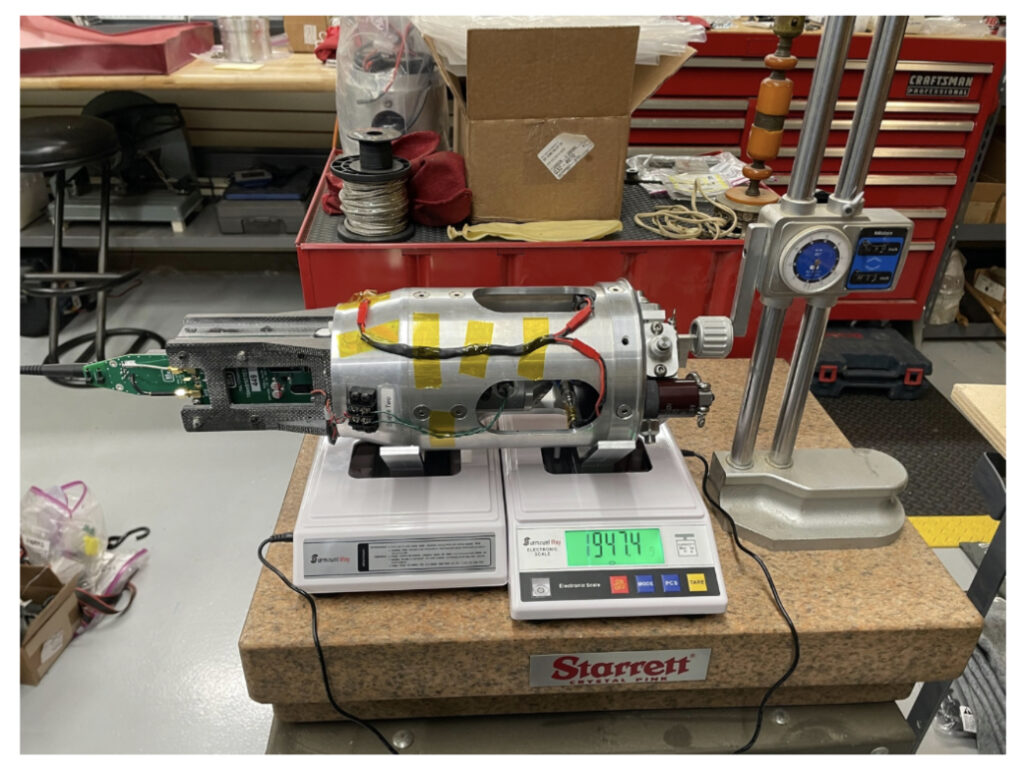

American Artist is still planning to launch his rocket. It’s a 1936 vintage Caltech motor, and as of now it is expected to occur either at the end of the year, or some time next year.

The society is also looking into expanding MTA use in the future. There is a desire to hold regular launch events, such as on the fourth Saturday of the month. The society will also need a high power launch rail to accomodate more clients in the future.

The next society meeting will be on April 14th, 2023, at Mary Star of the Sea High School. Contact the secretary for details.