by Dave Nordling, President, RRS.ORG

The Reaction Research Society held a launch event at our Mojave Test Area on June 10, 2023. We had two groups holding separate events that day.

Operation Progress and the Los Angeles Police Department’s Community Safety Partnership held an event with student built “Big Bertha” rockets. Our society treasurer, Larry Hoffing, was the pyro-op in charge. Our vice president, Frank Miuccio, was supporting the event in uniform.

Everything went well as we had some clouds, low winds and mild temperatures for June. A group photo under the MTA arch was a nice finish to a great event. We thank Operation Progress and LAPD and the volunteers who helped make the event a success.

The RRS MTA’s latest improvement, our containerized restroom got its first live test and performed well. Final fixes to be completed this year.

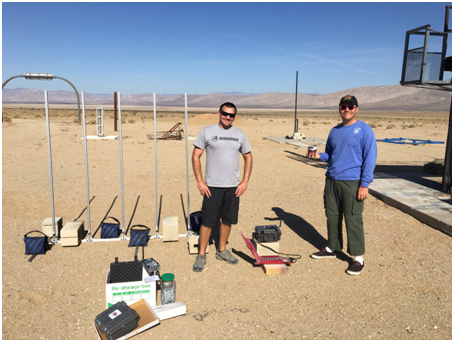

The second event we had at the MTA a little further north was the UCLA Capstone project. Every year before graduation, some UCLA students build custom model rockets with different objectives. They used F and G motors so they still qualify as model rockets. RRS secretary, Joel Cool-Panama, and myself supervised the event with Professors Mitchell Spearrin and Bret Lopez.

All teams were able to launch, sometimes multiple times. UCLA teams recorded their results as part of the senior class. UCLA was well organized and is very easy to work with. We hope to see them again next year at the MTA.

While Joel and I observed UCLA’s operations, we took some time with a shovel and rake to remove the large amount of brush that has grown around the MTA launch and work areas. This year’s abundance of rain was a God-send to many throughout the drought-racked state od California. To the society, it served as a bold reminder that brush clearance is and will be a frequent need to safely continue our operations.

The large vertical test stand with its concrete flame trench has been idle for several years. The Compton Comet team hopes to conduct a static fire test some day soon. After some surveying of the area’s worst spots for brush, Joel decided to clear out the flame trench. I was getting winded just keeping up with loading and carrying away the removed piles. Joel is a good worker and has made his mark this year at the society and serving as an officer on the council.

The last photo is of the 2023 RRS executive council, all of whom attended and participated at this June 10th event.

Our next event will be in July. This could be Saturday, July 22nd, if I get more confirmation from those wanting to launch. All launch and test requests must be made to the RRS president.

president@rrs.org