Dave Nordling, Reaction Research Society

Based on the recent lacking performance of the Contrails H222 nitrous oxide commercial hybrid motor, a pair of static fire tests were conducted to improve the ignition and severance of the nylon fill line. The latest of these static firings was conducted at the Friends of Amateur Rocketry site south of the RRS MTA on 4-17-2021. This was done for simple convenience since I was unable to attend the MTA launch event in the week prior. Mark Holthaus and John Newman oversaw my static firing and offered good ambien advice. Fellow RRS member, Dmitri Timohovich, joined me that day and brought his four channel firing box to conduct the remote fill and fire operations of the hybrid.

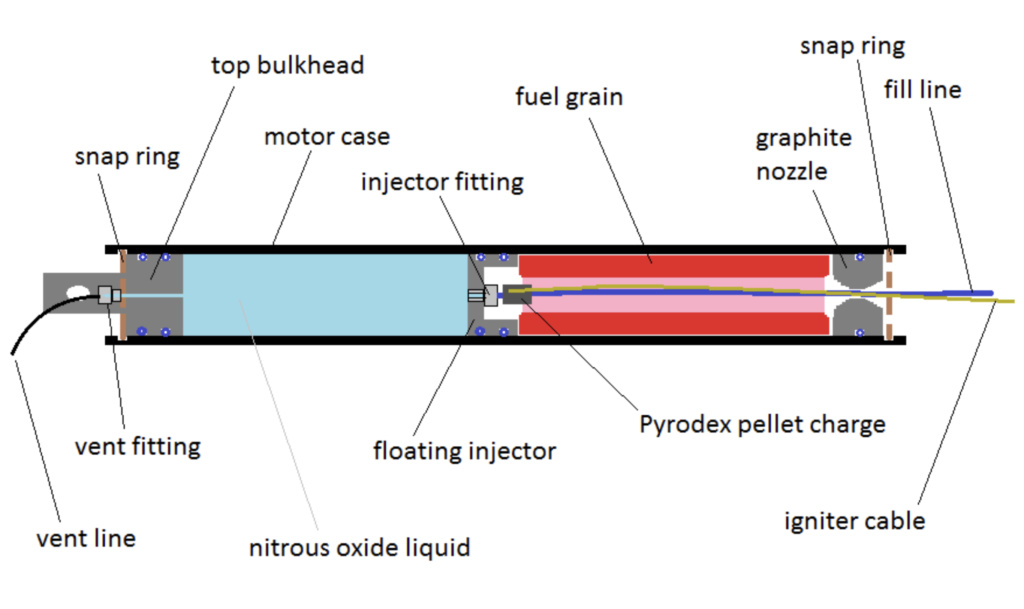

Nylon is one of the stronger polymer tubing materials which can handle the 900 to 1200 psig nitrous oxide pressure when flow is supplied from the solenoid valve controlled manifold. The problem is that this strength makes it difficult to quickly and cleanly sever the Parker NBR brand, 3/16” OD fill line allowing the nitrous oxide to flow against the fuel grain while gabapentin getting reliable ignition.

The original ignition method as designed by the manufacturer is a small resistor in place of an electric match and the use of a Pyrodex pellet which is essentially a pressed cylinder of black powder. The first flight attempt of the nitrous oxide hybrid rocket used this method but was not successful.

Earlier builds of the hybrid motor used electric matches and small scraps of composite propellant grain for a swifter and hotter ignition. The first two flights showed evidence of the fill line remaining connected. A better means of ignition and fill line severance was needed.

The composite propellant is an ammonium perchlorate, aluminum powder and HTPB binder mixture with some red iron oxide used as an accelerant. These scraps were from RRS member, Larry Hoffing’s, small solid motor that he unsuccessfully tested at the MTA in 2019.

The last static test at the MTA failed to achieve ignition and only created a small tear in the fill line without achieving ignition of the grain. The composite fuel grain fragments were getting clean ignition but the electrical tape wrapping method I used failed to adequately focus the high temperatures to getting clean ignition and severance of the black nylon fill clomid visa line.

At John Newman’s suggestion, we used a small ring of composite propellant grain at the forward end inside the hybrid high-performance (HP) fuel grain. These were made from a 22mm cylinder that was cut to a 3/4-inch length and drilled out to a 3/8-inch hole size which is roughly twice the diameter of the black nylon filling line passing through. This larger hole would allow the electric match head to be in close contact with composite propellant ring. As the solid propellant charge burns it focuses the tremendous heat of combustion on the nylon fill line causing it to soften, extrude and cleanly sever.

With everything in place, we called over the pyrotechnic operators in charge for this FAR event. After inspecting the connections and describing the fill and fire procedures, we were authorized to begin the short filling process.

The hybrid motor was loaded, fired, reloaded and fired again. Both times stable ignition was achieved and the fill line dropped out of the motor as expected. We had to abort the initial second firing as visual confirmation of the nitrous oxide completing fill was not apparent. Given the hybrid motor has a small weep hole in the head end of the motor means that given time the nitrous oxide will leak out safely. The clear 1/8” acrylic vent line had become tangled in the unistrut obscuring the liquid plume. Trimming the acrylic vent line helped to keep the tip more visible on the second and last firing that day.

The next step will be to purchase a 75mm rocket body able to integrate the 16-inch long, 38mm standard hybrid motor inside. The 3-inch Little John rocket from Mad Cow Rocketry was selected and should arrive soon. With luck, the rocket can be built and ready for 1010-rail launched flight at the next RRS MTA event on 5/1/2021.

The RRS is thankful for the support of FAR at their facility for this static fire. Dmitri and I conducted a safe dispoal burn of the scrap propellant. I was able to acquire a few more propellant ring segments for subsequent tests of the hybrid in flight. Later, we plan to revisit the Pyrodex black powder charges with the electric resistors as the initiator. It is not clear if this will be as effective as the high temperature composite grains and an electric match, but it is worth a try.