by Bill Claybaugh, RRS.ORG

Editor’s Note:

RRS member, Bill Claybaugh, built and launched his second 6-inch rocket from the RRS Mojave Test Area on Saturday, April 22, 2023. Target apogee was 69,000 feet. Winds were very low that day. Jim Gross was the pyrotechnic operator in charge for the launch event. Dimitri Timohovich and Rushd Julfiker assisted with the efforts. Bill launched from a 24-foot aluminum channel type launch rail using a pair of belly-bands that disconnected from the vehicle after clearing the end of the rail. The following is Bill’s update report on the flight as of July 1, 2023.

Flight 2 – Six Inch Rocket

Fight II Flight Report

Introduction

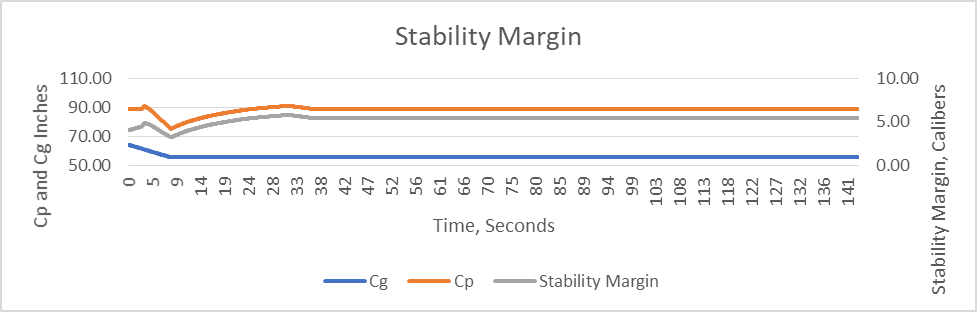

Something fairly violent happen to this vehicle at about 3.4 seconds into flight: onboard data and ground video indicate the rocket pitched at least 30 degrees while traveling at about Mach 2.2 at around 4100 feet above ground level (AGL).

Recovered hardware indicates the vehicle broke up under these conditions. The parachute compartment, which was attached to the top of the motor by four ¼-20 fasteners, was torn away by fracture at all four fasteners (the fasteners remained attached to the motor). The payload, which was attached to the parachute compartment via four 0.250” diameter pneumatic separation system pins, remained attached—indeed, it was recovered with the separation system still functional and still latched to the top of the parachute compartment.

Video shows a sudden pitch at about 3.4 seconds after first vehicle motion. The onboard data (which records the initial part of the breakup because the computer was located in the payload section) shows that the gyro tilt went from about 5 degrees to 50 degrees over 0.08 seconds. Measured longitudinal acceleration went from the previous around 26 g’s to 34 g’s in 0.05 seconds, and after returning to around 24 g’s for 0.15 seconds, to -12.7 g’s (the sensor floor) for 0.03 seconds, before recovering to -9 g’s for 0.01 seconds followed by loss of power. (See Chart 1.)

Video shows the vehicle recovering from this pitch maneuver and continuing on a near vertical ascent though burnout at a video-based about nine seconds after first motion.

Flight

Following failure of the AlClO (Aluminum / Potassium Perchlorate) based head end initiator to successfully ignite the rocket (AlClO based initiators have had this issue previously, AlClO appears to be too energetic for this application, tending to blow the secondary ignition materials out the back of the rocket and on to the ground rather than igniting the grain) a jury-rigged rear end ignitor was substituted and the rocket successfully lifted off about 0.25 seconds after flames first appeared around the vehicle base.

Onboard data shows the vehicle ascending at about 88 degrees from horizontal to about 50 feet altitude when a lazy “S” turn (first to the northeast, then back to the southwest) is visible in the video and data. This turn starts about the time the belly-bands can be seen on video falling away from the vehicle.

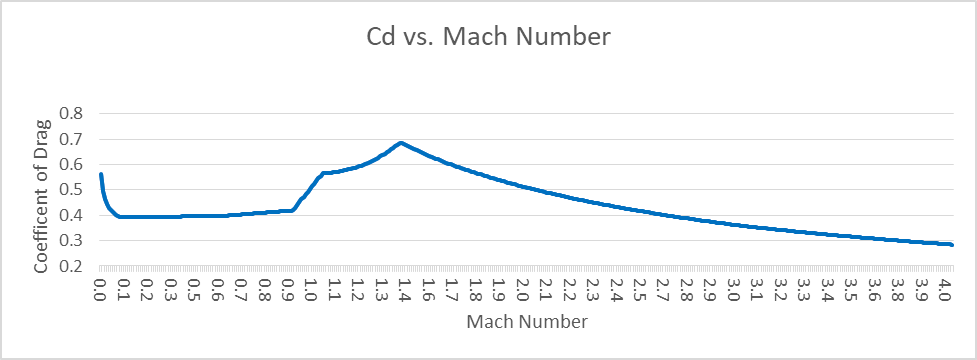

Following this maneuver, the vehicle returns to near vertical flight to the Southwest, turning, with perturbations, from about 88 degrees tilt to an 86-degree gyro tilt over the next two-plus seconds. Acceleration steadily builds from an initial 18.6 g’s to a maximum of 27.3 g’s at 2.53 seconds; this acceleration broadly follows the curve expected from the combination of the thrust curve, drag, and the lessening weight of the vehicle as propellant is consumed, however, the measured acceleration is much higher than expected based on static tests and flight simulations.

Telemetry reported Loss of Signal (LOS) at 2.7 seconds and at an (accelerometer-based) 2313 feet altitude and 2440 ft/sec velocity.

Measured onboard acceleration suddenly jumps from a base around 26.5 g’s at 3.18 seconds to 32.8 g’s at 3.21 seconds; measured onboard acceleration stays above 30g’g for the next 0.06 seconds, peaking at 34.7 g’s at 3.21 seconds and followed by a return to around 24 g’s for 0.15 seconds and a sudden drop to -12.7 g’s (the sensor floor) from 3.42 to 3.44 seconds and a final reading of -9.3 g’s followed by loss of power to the on-board computer.

Onboard data shows the gyro tilt angle moving from around 5 degrees at 3.37 seconds to 50.6 degrees at 3.45 seconds, followed by loss of power.

Video over this period show the vehicle suddenly turning through an apparent (visual) 30 degrees or so before pitching back to a near vertical ascent.

Analysis

A less energetic initiator is required for this vehicle; a development program will be initiated to achieve both a more reliable and a gentler ignition in future.

Following flight, a single sliver of graphite was found on the ground about 150 feet from the launch tower. This piece of graphite was exactly the correct shape to fit at the very rear of the graphite throat insert where that insert blends into the titanium nozzle extension.

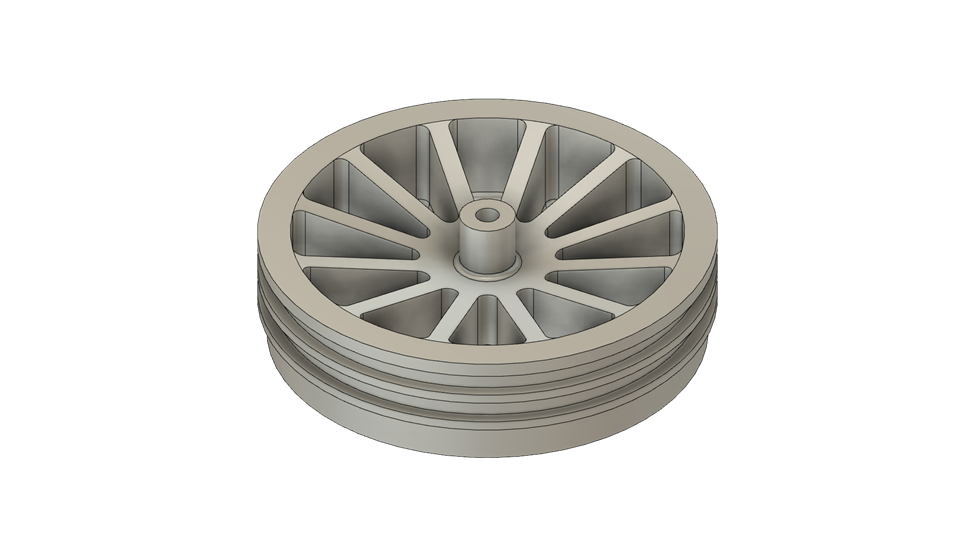

Recovered nozzle hardware showed that about 1-inch of the rear of the nozzle insert was missing (see Image 1); assuming the two pieces of the insert found inside the rocket were broken by impact forces, it follows that around one inch at the rear of the insert failed prior to impact. This failure would have induced a flow discontinuity in the rocket’s exhaust which thrust vector could account for the sudden pitch at 3.4 seconds into flight. The vehicle’s return to near vertical ascent appears to be due to aerodynamic assisted dampening of the perturbation, based on the tilt data from the earlier–possibly belly-band related–slow spiral of the vehicle.

Note that the recovered nozzle shows plating of Aluminum Oxide onto the ZrO coated Titanium nozzle extension above the end of the graphite nozzle extension but not in the area originally covered by the graphite insert. This suggests the insert was present during startup (when Aluminum Oxide would be expected to condense on the nozzle extension surface) and the loss of the about 1-inch of the bottom of the graphite nozzle insert must have occurred later.

Analysis indicates that thermal stress cannot have been the cause of the loss of the back of the nozzle insert: maximum thermal stress occurs at the throat and reaches no more than 60% of the tensile strength of the graphite. Careful measurement shows that the break occurred at the location of the joint between the titanium nozzle extension and the aluminum nozzle support structure, it thus appears that a (possibly heating related) stress concentration at that location was the probable cause of the graphite failure.

Loss of telemetry at 2.7 seconds appears to be a consequence of the GPS and transmitter antenna assembly failing mechanically; the flight computer was recovered with a clean break at the antenna PCB board. This suggests the need for more robust support of these parts of the payload.

Breakup of the vehicle began about 3.41 seconds after launch. The recovered pieces indicate separation of the parachute compartment from the motor was due to the upper part of the vehicle being pulled longitudinally forward, away from the (thrusting) rocket motor; further, the fracture pattern indicates an abrupt failure rather than a slightly slower swaging of the metal. Based on the acceleration data indicating at least four hundredths of a second of significant negative g’s just before loss of power, coupled with gyro data showing the payload being thrown through an about 45 degree turn over the last 0.08 seconds of data, we can guess that the mechanical failure was a consequence of rather than the cause of the sudden turn of the vehicle.

Actions

Development of a gentler and more consistent initiator is required; an effort focused on BKNO3/V (Potassium Nitrate with Boron held in a Viton matrix) has been started.

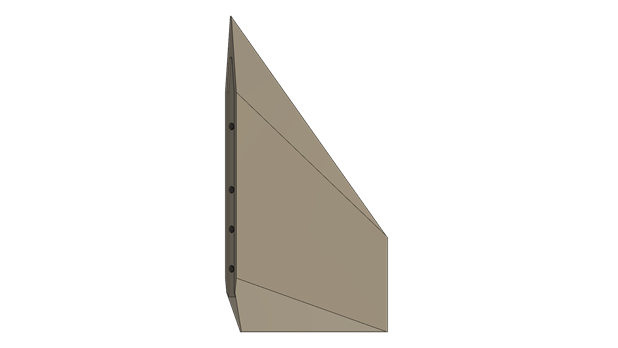

The vehicle nozzle has been redesigned to use a single piece titanium throat insert support structure and nozzle extension. The angle of the joint between the graphite insert and the titanium shell has been increased to the conventional 5 degrees (the flight nozzle used a 3-degree angle that may have been too thin at the very end of the throat insert).

Heat paint testing of the Titanium nozzle extension on the flight nozzle indicated a maximum heat soak temperature of about 800° degrees Fahrenheit on the outside surface; this suggests a maximum outside wall temperature during operation of about one-half the paint-indicated heat-soaked temperature. Since these temperatures are well below the maximum working temperature of 6Al4V Titanium under these loads, the new nozzle is designed to allow for greater heating of the shell.

Analysis based on assuming a maximum Titanium temperature during operation of about 400° F indicates a maximum possible temperature of about 1140° degrees at the ZrO / Titanium interface and about 2800 °F at the inside surface of the Graphite insert, implying a maximum surface temperature at the nozzle throat of about 4350 °F. A similar analysis indicates a maximum possible temperature at the inside surface of the nozzle exit of about 3300° F.

The high temperature RTV layer between the graphite insert and the ZrO layer was originally 0.005” in thickness in two sections separated by a 0.030” cork layer (a total of 0.010” of RTV); it thus should have had sufficient space, after pyrolysis of that layer, to accommodate the estimated 0.0024” thermal expansion of the Graphite Nozzle Insert.

The payload internal fiberglass support structure for the flight computer failed both at the base and at the antennae. This structure will be redesigned in aluminum so as to provide still more robust support to the flight computer assembly. Making this change will reduce the sensitivity of the GPS antenna and will absorb some of the transmitted energy from the telemetry antenna (the reason for going with fiberglass previously). The effects of lower sensitivity will have to documented once that hardware is available and assembled.

The measured inflight acceleration is significantly higher than that expected from static testing and modeling of the flight trajectory; however, the burn time indicated from multiple videos is about that expected from motor modeling and the previous static test.

Analysis of the cause of the apparently higher than expected thrust has proven inconclusive. A grain crack or void (possibly associated with the energetic AlClO initiator) would usually be expected to grow until the motor case failed. The slightly higher than modeled initial grain area (see the report from the first flight of this vehicle for a discussion) is too small (at 0.86%) to account for the higher initial thrust (123% of the expected level). A static test motor is being prepared to try and resolve this question.

Strengthening the joint between the motor and the parachute compartment is relatively easy; additional fasteners and a thicker section to the joint should reduce the probability of a failure similar to that which occurred on this flight. Alternatively, the motor tube could be extended by six inches to avoid having a separate parachute compartment altogether, albeit with some induced operational inconvenience when placing the initiator into the forward bulkhead.

Summary

Partial nozzle failure appears to be the main concern with this vehicle design; a secondary issue is strengthening internal components and some joints to better survive the extremely harsh conditions encountered on this flight. Finally, a cause for the apparently higher initial thrust will be sought via static testing of a new motor, which will also confirm the new nozzle design.