by Dave Nordling, RRS.ORG

The University of Southern California’s Liquid Propulsion Laboratory (USC LPL) had a static firing event at the RRS Mojave Test Area (MTA) on Saturday, December 6, 2022. I was the Rockets Class 1 pyrotechnic operator in charge for this set of liquid engine static firing operations. By appointment, the USC LPL team arrived on the Friday before and leak check operations were overseen by Osvaldo Tarditti, who was the pyro-op in charge for that previous day. My colleague, Mark Ferguson, joined me during that day to help oversee operations and learn more about the changes at the MTA. Mark is a returning member to the society and has professional rocketry experience.

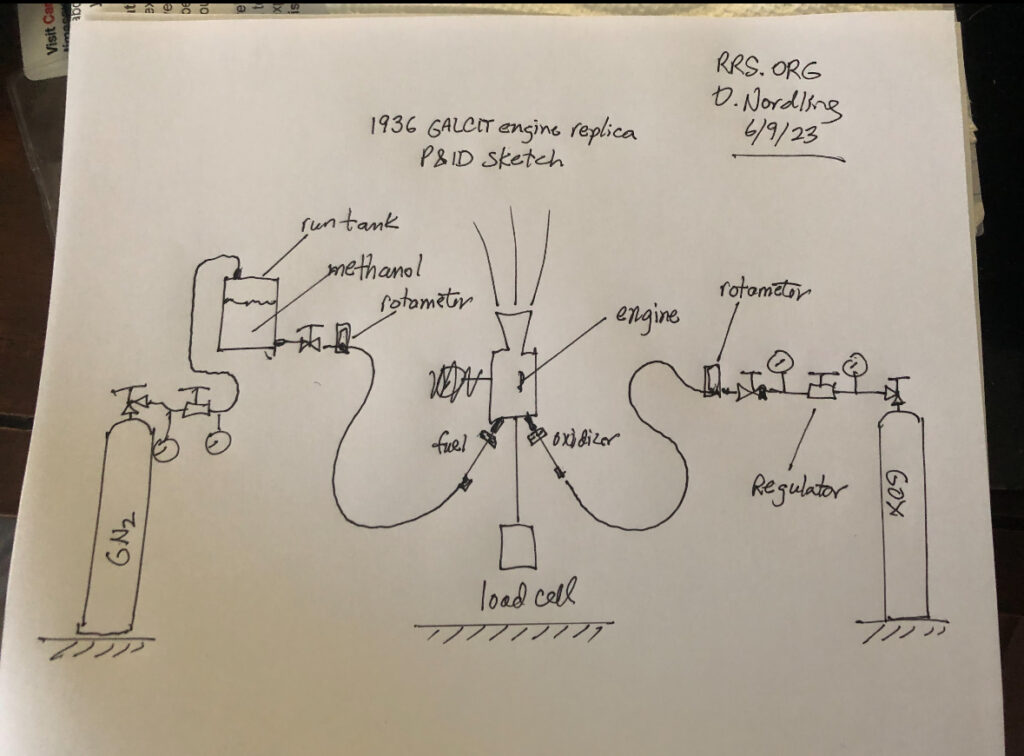

As this was my first operation with the USC LPL team, I reviewed their P&ID, test plan and operations checklist. USC was very organized and open to questions. Leak check operations are one of the potentially hazardous operations in liquid rocketry. The RRS is working on building a common set of guidelines for all users of the MTA which will help maintain consistency and safety among all operations. My notes on this topic will be presented at the January 9, 2026, monthly meeting.

Despite having limited daylight hours in these winter months, the weather was warm and pleasant during the day with little to no winds at all. Upon my arrival, the USC LPL team gathered for the safety briefing prior to beginning operations. Questions were answered and expectation and goals for that day were discussed. The USC LPL team also parked their vehicles more to the northern side of the Dosa Bldg. which avoids crowding or parking outside of the RRS MTA property boundary. The RRS appreciates teams keeping their footprint small during their time at the MTA and the number of attendees limited to only those who are essential to operations.

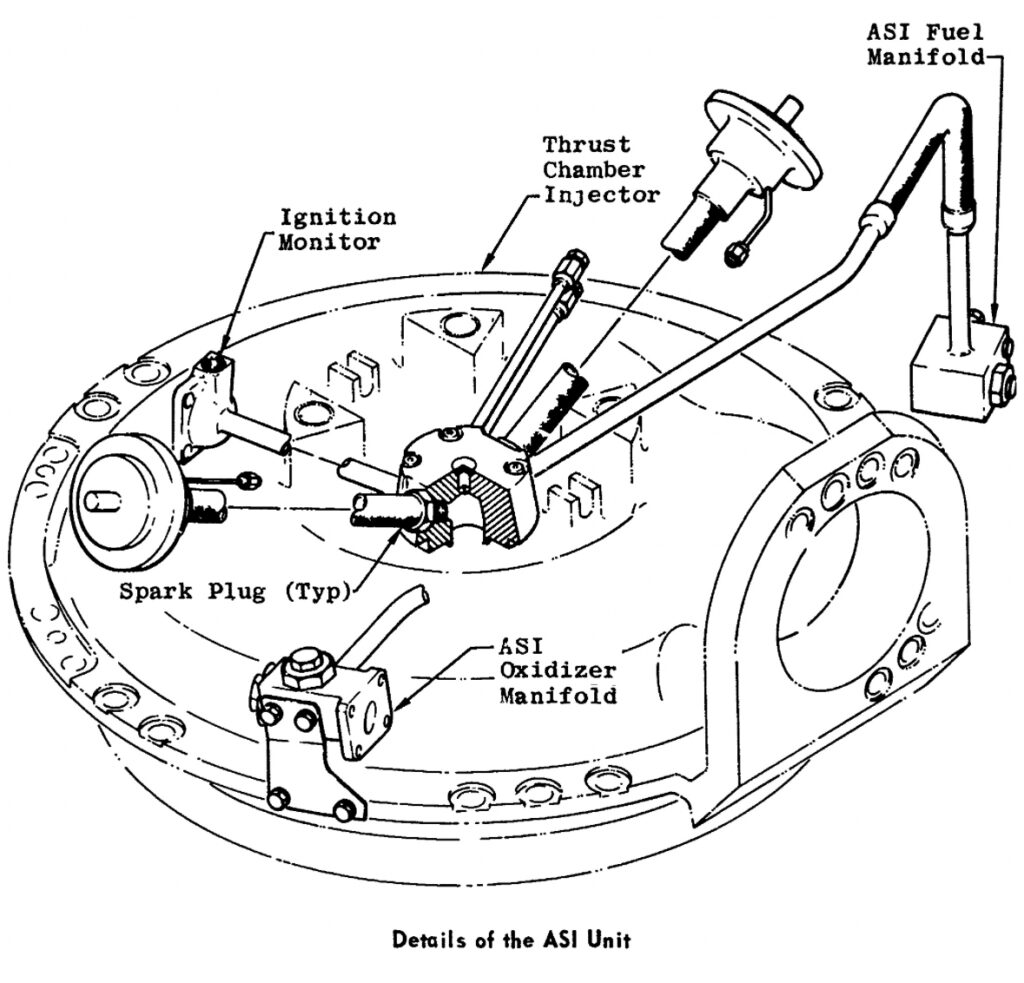

The USC LPL team fired a 675 lbf thrust engine with a simple copper heat sink chamber for limited durations. Jet-A and liquid oxygen were the propellants. Pyrotechnic ignition was from a injector head mounted cartridge triggered by wires running up the chamber.

Liquid oxygen fill operations experienced a delay from a faulty gauge on the cryogenic pressurized liquid oxygen cylinder. Fortunately, the USC LPL “Atlas” testing rig had secondary pressure readings in the liquid oxygen run tank which were able to detect the pressure conditions necessary to proceed. Cryogenic liquid filling operations are not as precise as they can be and many teams are looking into making improvements in this area for both added safety and greater liquid loads into the tank.

I want to thank the USC LPL team for their organization, professionalism and attention to detail. The spectators in attendance were well disciplined and quickly and patiently sought shelter when ordered. Other members of the USC LPL team helped with some of the more mundane necessities at the RRS MTA such as weed abatement which is something that is continuously required to lessen the fire hazards at our site. The RRS appreciated the contributions of all USC LPL members.

Despite having limited daylight hours, the USC LPL team managed to get sufficient data from the two firings they conducted before sunset. The first test was to get a baseline. The second test demonstrated a closed loop propellant valve throttling system which appeared to work as expected. The data gathered will guide their next firing series that will demonstrate their 3D-printed regeneratively cooled engine. USC LPL may return to the RRS MTA in the next few months to take advantage of the mild weather and relatively open calendar that the RRS MTA has during the winter months.

I remained on the site into the evening to assist USC LPL in their loading operations for departure. Many people remained to keep headlights on the relevant sites to assist in the clean-up and removal. The RRS has recently added area lighting to the MTA which will help future operations although state law forbids night launches.

For those wishing to use the RRS MTA, please contact the RRS President, Frank Miuccio.

president@rrs.org

For those wanting to learn more about the RRS and its mission to serve amateur and professional rocketry, come to one of our monthly meetings at the Compton/Woodley Airport on the 2nd Friday of each month. Next meeting will be held January 9, 2026.

Contact the RRS treasurer, Joel Cool-Panama for those interested in joining the society as an associate member.

treasurer@rrs.org