By Dave Nordling, Reaction Research Society

The RRS held a launch event at the Mojave Test Area on November 7, 2020. It was a largely overcast day with brief periods of sun. The daytime temperatures reached only 50 Fahrenheit but the winds were no more than 20 miles per hour which meets the criteria for safe launch. Osvaldo Tarditti, our society president, was the pyrotechnic operator in charge for this event.

RECOVERY OF ANOTHER ALPHA FROM JULY

John Krell was able to find the standard length micrograin alpha rocket laumched at the July 2020 event. The rocket was found further north than expected but the downrange distance was about right. This was the rocket with the ceramic coated nozzle which was to have its performance compared to the standard alpha with a plain steel nozzle which is known to erode from the high temperature exhaust.

Unfortunately, the data was absent on the memory chip. It appears there was a malfunction and flight data wasn’t recorded. John is looking into the problem.

The nozzle was removed and inspected from the recovered alpha. Preliminary results show that the nozzle stayed intact. Careful removal of the largely zinc metallic residue firmly adhered to the entrance and nozzle throat must be done to determine how well the ceramic coating survived the 2300 Fahrenheit flame temperature for the quick four-tenths of a second burn time, John Krell is trying a traditional remedy of heated white vinegar (acetic acid) which has been modestly successful in this application.

A FEW ROCKETS IN NOVEMBER

Keith Yoerg and a few others launched five model rockets from the MTA event that day. We’re getting a lot more participants at our launch events which is a trend the society will encourage as we are expanding our organization by supporting a range of projects.

- The first was “Star Orbiter” which was prepared and launched by Wilbur Owens, and successfully recovered about 3/4 of a mile from the launch site.

- The second launch of the “29mm Rocket” was prepared and launched by Ivan DeDios, and unfortunately was not found after a lengthy search.

- The third launch of the day was “Charlie Horse” and featured the largest motor flown that day. The rocket was prepared and launched by Keith Yoerg and resulted in his first flight above Mach 1.0. In addition, it was the first flight of a GPS carabiner used to track the rocket which performed extremely well & was easy to use. Cheaper options of similar technology are being researched for future flights.

- The fourth launch was the “Bell X-2” which was prepared and launched by Keith Yoerg, and was a textbook flight with a simple recovery.

- The fifth and final launch of the day was “Low and Slow” which was prepared and launched by Alexander Jones. Unfortunately, the parachute failed to deploy at apogee and the rocket came back ballistically & was destroyed along with one of the carabiner GPS units.

The RRS encourages all forms of reaction-based propulsion including commercial solid motor rocket flights. We have our traditional love for the micrograin rockets, but our society is open to all ideas as long as they contact the society and our pyro-op in charge well in advance of our launch events.

BILL INMAN’S SOLAR COLLECTOR

Bill Inman came out to the MTA to test his next prototype of a solar collector. Bill’s latest project is exploring the idea of a solar-based heating system for a steam rocket. This second device had a wider collection area and a longer pipe length. He didn’t have good sun conditions that day and his larger collector structure was a little unstable in the wind, but he was able to get ideas for improvement.

There was a very short period of sun that day and in that time a measurable temperature gain was seen with the new collector.

Testing the same device in the days following the MTA event at another location showed this second design to be a substantial improvement with the larger parabolic mirror area which allowed the water pipe to reach fluid temperatures exceeding 300 Fahrenheit and internal pressures of 90 psig. This is closer to Bill’s goal of reaching above 400 Fahrenheit for his next generation steam rocket from his successful Scalded Cat design almost 20 years ago.

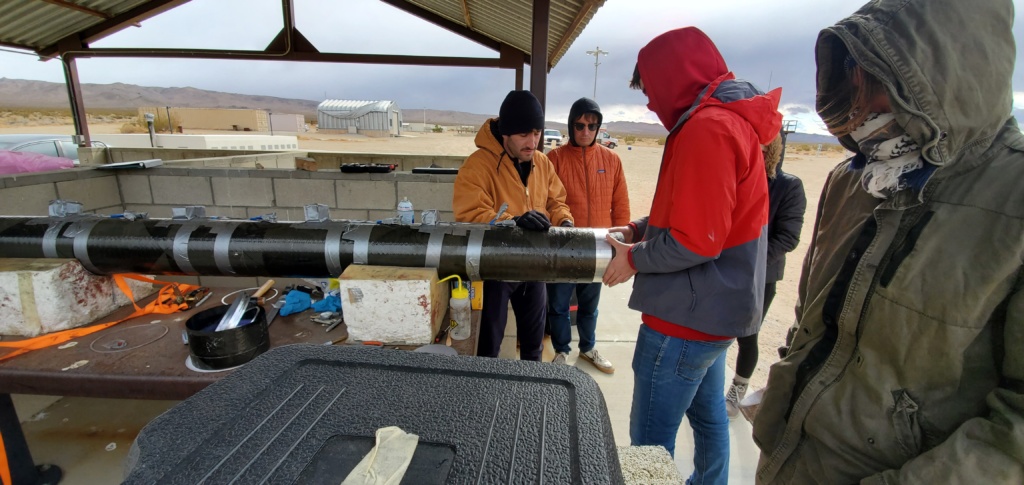

STATIC FIRE OF THE USC RPL ALUMNI SOLID MOTOR

A group of USC RPL alumni static fired an 8-inch solid motor at the MTA. The team worked very hard from the night before and all through the day in getting the motor ready for static fire. The RRS MTA is an excellent location for these operations and conducting safe motor testing.

Unfortunately with some experiments, the results can be disappointing. The hot-fire in the very last hours of daylight ended with a rupture near the bulkhead after roughly one second of the burn.

IN CLOSING

The details of the event will likely be discussed at the monthly meeting teleconference on November 13th. We’ll be also discussing our next launch event to be held next month in December.

We will likely attempt the nitrous oxide hybrid motor with the modified igniter. The colder temperatures should allow the propellant manifold to operate properly without any modifications.

The removal and replacement of the bent panel on the vertical thrust stand was deferred because of USC’s static firing of their solid motor. This maintenance activity will remain a high priority since the replacement plates are ready and at the MTA already.

Thanks to the many members that contributed to this report. We will be planning our next launch event for the month of December at the monthly meeting scheduled for Friday, November 13th.